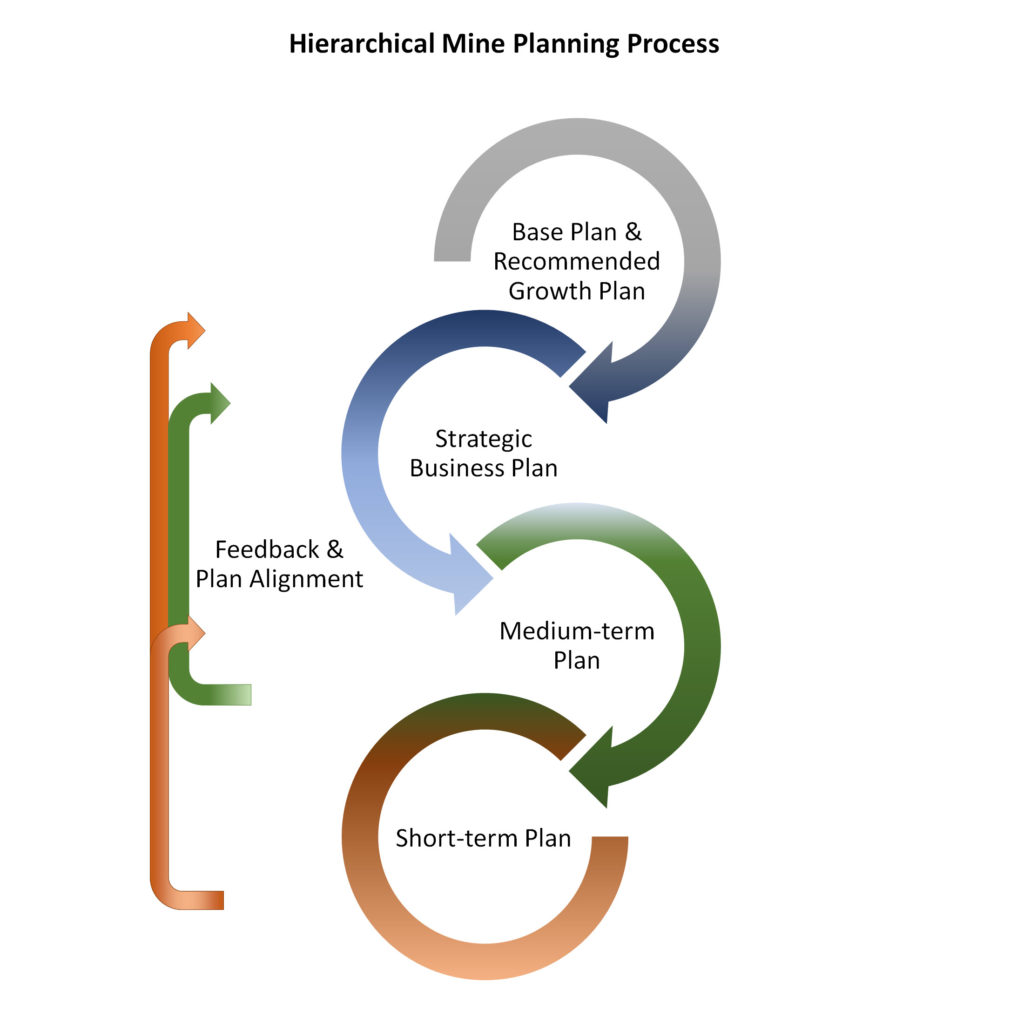

Over many years working as a mine planner I have had the opportunity to participate in the preparation, presentation and implementation of mine plans at various levels and locations. A question that I have often heard asked is “What does a good mine planning process look like?” Mine planning is a hierarchical process which requires a collaborative approach, involving a wide range of stakeholders, both internal and external to the organization. It must be driven by the company’s senior management and appropriately governed at Board level. Here are the steps I would typically follow to set up a best practice mine planning process.

1. The Base Plan

To start, every mining business should produce a Base Plan. This represents an optimized, strategic, sustainable base case position. It is sometimes referred to as a “stay in business” case and represents the best life-of-mine plan that can be produced without any significant capital being spent on bringing additional resources/reserves on line, and without any growth or expansions to production capacity. This plan just runs out to the natural end of reserve life using sustaining capital to maintain what you have in terms of deposit reserves, infrastructure, plant and equipment. It must also take into account mine closure and rehabilitation costs.

The Base Plan is an optimal strategic mine plan that sustainably delivers best value to its stakeholders as a minimum stay-in-business case.

So, what makes the best base plan? Well, since any mining business should focus on sustainably delivering value to its shareholders/owners, the best base plan will generally be the one that does just that, subject to the constraints mentioned above. But this strategic plan must be practically achievable as well and this is often where strategic planning falls short of the mark. Feedback from mine operations management and mine planners who typically have the most up-to-date practical knowledge of the mine’s operating conditions is critical. As a strategic mine planner, you must seek their feedback, understand it and incorporate it into the strategic mine plans.

2. The Recommended Growth Plan

The next vital step, whether you’re in boom time or struggle town, is to evaluate a wide range of options to determine the Recommended Growth Plan. Once again the objective is to sustainably deliver maximum value. This recommended growth plan will typically include some investment in growth via several means, such as exploration, acquisition and/or capital expenditure.

The Recommended Growth Plan elaborates the base plan further to account for possible investments for project growth.

There will also be some constraints to growth. These could be imposed by your company’s Board or senior management, infrastructure- or market-related, due to environmental or social factors, or some combination of these. But strategic planners must always challenge these constraints to make sure that they really are hard constraints, rather than just assumptions that have been imposed without any justification. Challenging these constraints is key to identifying the best path to value for your business. As a strategic mine/business planner, part of your job is to help your senior management and Board do just that. The fewer constraints you start with, the better the opportunity you have to find the truly optimal strategic schedule for your mine.

3. The Strategic Business Plan

Together, the base plan and the recommended growth plan form the basis of the Strategic Business Plan which is typically prepared by a strategic mine planner and submitted to the company’s senior management for approval. Once prepared and approved, the strategic business plan must be effectively communicated to all key stakeholders, both within your organisation and externally. The best plan in the world is no good to anybody if all it does is sit in a report on a shelf gathering dust. The strategic plan needs to be regularly updated to ensure it remains workable. Often, this is an annual cycle, but the frequency of updates is really a matter for your own business to decide.

The Strategic Business Plan is derived from the base and recommended growth plans and must be regularly updated and communicated to stakeholders.

The important thing to remember here is that the strategic plan needs to be updated according to the actual state and the current knowledge of your business and not the superseded information that made up your original feasibility study. Feasibility studies are completed at a given point in time and generally serve a particular purpose, e.g. to prove the feasibility to invest in a particular mining project and to assist with obtaining funding to do so. Things like the changing needs of the business, increased knowledge/understanding of ore bodies and hard-earned experience gained during operations will inevitably mean that a feasibility study’s mine plan will very quickly become out-of-date.

4. Medium-term Plans

The strategic business plan then drives the direction of your Medium-term Mine Plans. Typically these are 2-5 year timeframes, but again, the parameters are up to your business to decide.

The Medium-term Plan is typically 2-5 years long and it must be aligned with the objectives set in your strategic business plan.

The medium-term plan may be simply the first 2-5 years of the strategic plan, with a bit more added granularity to allow for more detailed budget planning, or it may be a separate plan put together by a different group of mine planners. Whatever the case, it must focus on efficiently delivering the objectives and milestones that have been set in the strategic plan. This ensures that the maximum value that has been identified in the strategic business plan is delivered. Of course, situations will arise where the two planning horizons will be in conflict. That’s where constant collaboration and feedback between those responsible for the medium-term planning and strategic planning functions is essential.

5. Short-term Plans

Short-term Mine Plans are then developed on a rolling basis. Typically these have time frames ranging from three-month forecasts to monthly, weekly and daily equipment-based production plans.

The Short-term Plan is typically developed on a monthly or weekly rolling basis and must be both aligned with the medium-term plan, and flexible enough to deal with operational variability.

At the shortest time frame, these plans form a clear, concise set of instructions for mine operations to execute in the field; for example, where to prepare the next bench or drill pattern, which shot is being fired next, where the shovels are digging and where the dirt is being hauled. Once again, alignment between the short-term and medium-term plans is essential. However, the short-term plan should still retain adequate flexibility and agility to deal with variability in key operating factors such as grades, short-term stockpile levels, equipment downtime, weather conditions and other environmental factors.

Aligning the Different Planning Levels

In my experience, for a mine planning process to be considered best practice, all mine planning levels and horizons need to be aligned towards the primary objective, which is to sustainably deliver maximum value to the shareholders of the business.

Each planning level must adjust to uncertainties and still remain aligned with the next level to deliver maximum value to the business stakeholders.

All planning levels must be allowed, within an acceptable tolerance, to deviate from the next level plan, in order to account for uncertainties that can arise in the short term. The key is that each planning horizon is able to adjust its planning to account for these uncertainties and still maintain alignment with the next level of plan, whilst all the time providing feedback to the next level of plan to facilitate continuous improvement. This kind of collaboration ensures that each level of the planning hierarchy remains aligned with the primary business objective. What does a best practice mine planning process look like to you? Send me your comments using the contact form.