Mine planning processes are continuing to improve across the industry. Ten years ago, we paid little attention to strategic mine planning outside of carrying out pit optimizations. Since then, things have progressed and mining organizations have understood the necessity to go the next step and optimize strategic schedules to create high value strategic plans.

Sadly, one effect of this evolution is that the connection of the strategic planning process with the lower-level operational process has been an afterthought, often resulting in misalignment between the two levels. These days the industry agrees that there will be a loss of value if:

Sadly, one effect of this evolution is that the connection of the strategic planning process with the lower-level operational process has been an afterthought, often resulting in misalignment between the two levels. These days the industry agrees that there will be a loss of value if:

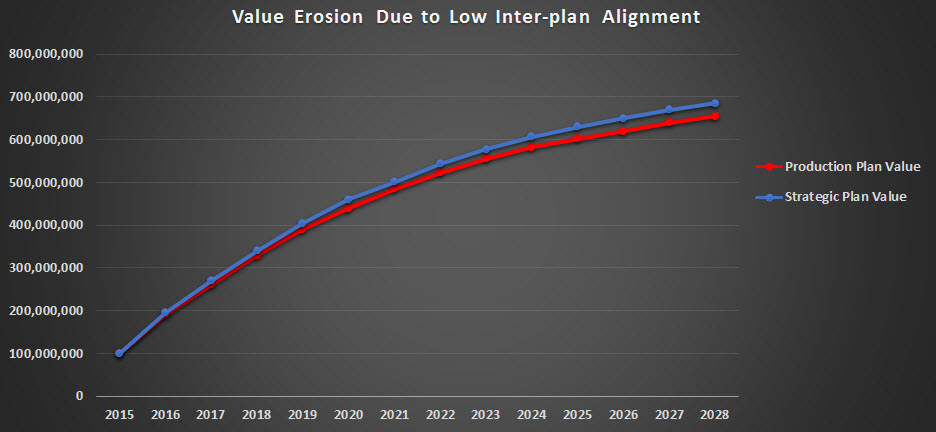

- The short-term (or production) plan does not follow the long-term plan (as shown in the chart)

- We respond to unplanned events at an operational level without considering the effects on the long-term plan

So what are the tactics we need so we can escape checkmate? In our new series, our authors address the issues of poor mine plan alignment with practical advice and tools on how to integrate the different levels of the mine planning process. In particular, they discuss the following topics:

So what are the tactics we need so we can escape checkmate? In our new series, our authors address the issues of poor mine plan alignment with practical advice and tools on how to integrate the different levels of the mine planning process. In particular, they discuss the following topics:

- What does best-practice mine planning look like?

- How to measure mine plan alignment?

- How to achieve alignment in short-term planning?

- What happens if your grade is not what was expected in your plan?

We hope our articles will give you a strategy to change tolerable mine plan alignment into a winning set of moves that give you the best possible value for your mine. You can subscribe to get news alerts delivered directly to your mailbox or follow Minemax on social media to keep in touch with the latest from Minemax.