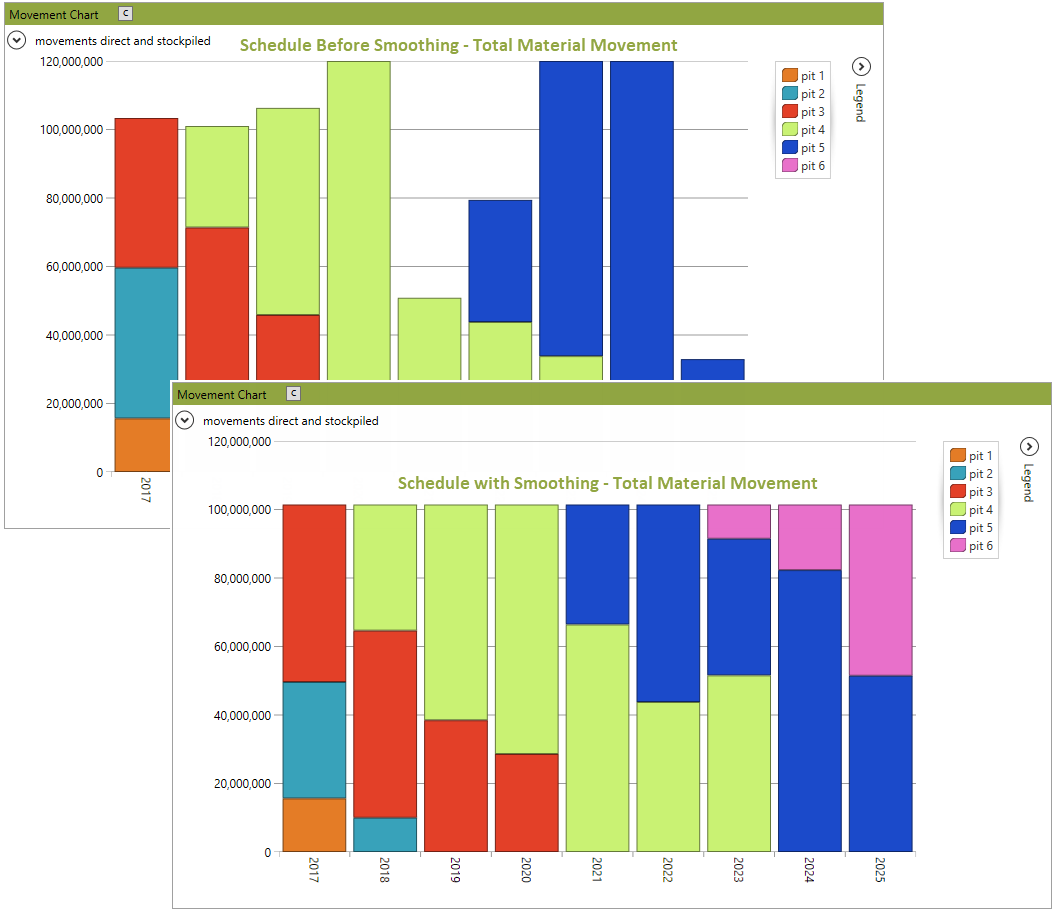

Strategic mine planners can spend days just trying to get a smoothed schedule – one where the trucking or total material movement (TMM) doesn’t have drastic peaks and valleys in it. This process can be frustrating and take up valuable time: when you fix one glaring dip or peak in the schedule, another one appears somewhere else.

The new smoothing constraints in Minemax Scheduler 6.4.1 give planners the ability to produce a smooth practical schedule without all those tedious manual iterations. The automated smoothing means more time for running additional scenarios or analyzing results, and there’s also the bonus of greater accuracy, and even a better NPV.

Minemax Scheduler’s new smoothing constraints accomplish this by giving engineers more control on the upward and downward differences in material movement from one period to another. You just need to set this up as difference constraints in your scenario and let the optimization find the best value schedule.

This new release also solves another problem planners have been struggling with: how to ensure enough waste is mined for infrastructural projects like roads and tailings dams before processing can begin. Minemax Scheduler’s new cumulative constraints make sure the necessary amount of waste has been mined for construction without over-constraining the schedule.

Minemax Scheduler 6.4.1 is available for download to all maintained users the next time you launch your Minemax Software Manager (MSM).

Contact our mining engineers to learn how these new constraints can help you create a smooth, practical schedule without sacrificing strategic value.