The traditional way of modelling material destinations in a strategic mine plan is to pre-determine the material paths when preparing the model. For example, in a gold mine project, we pre-define the destination of blocks with higher grades to be a Carbon in Pulp (CIP) mill and the destination of blocks with lower grades to be a heap leach (HL) dump. We also have an economic cut-off grade set up so blocks with grades lower than the cut-off grade are sent to the waste dump.

But the best option is not always obvious at the start and we may be able to realize more value by considering all possible options. We can do this by letting our schedule optimization software determine the material destinations. With this approach, you might see high grade material going to HL instead of CIP. This is because the CIP is at capacity with other blocks which have a higher grade.

In this short how-to article, we’ll show you how to use Minemax Scheduler to model alternative decisions that will treat material destinations as an output of the scheduling process so we can consider all the possible options for our project.

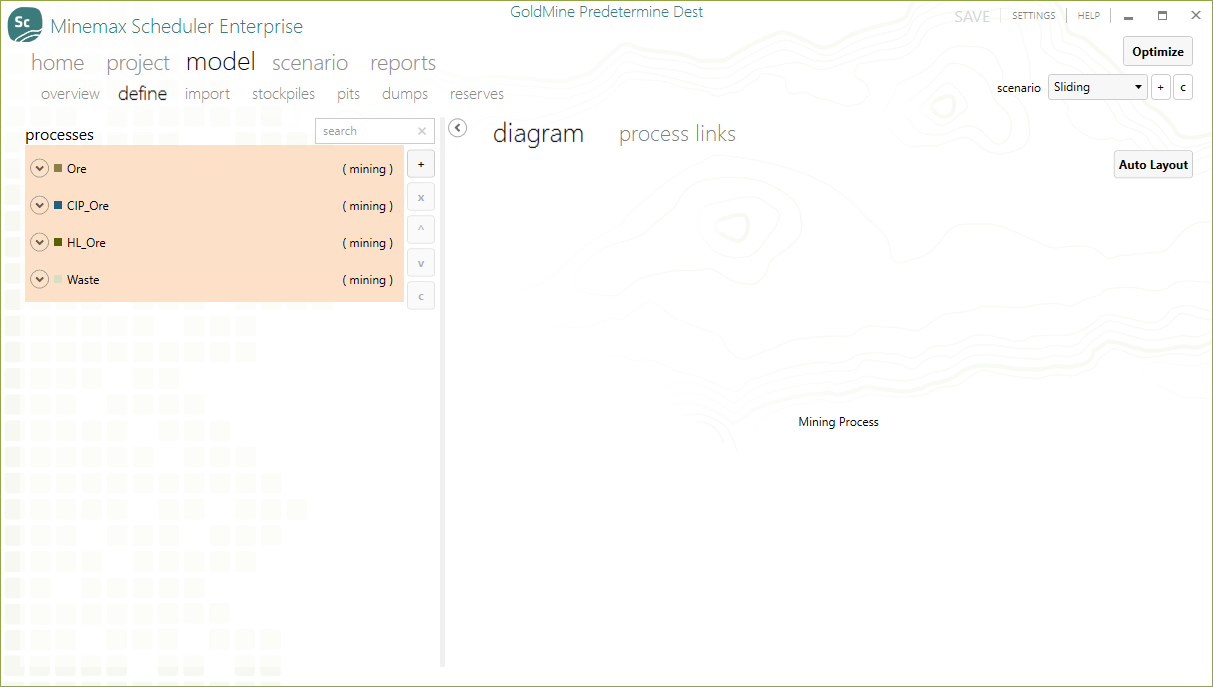

Modeling Predetermined Destinations

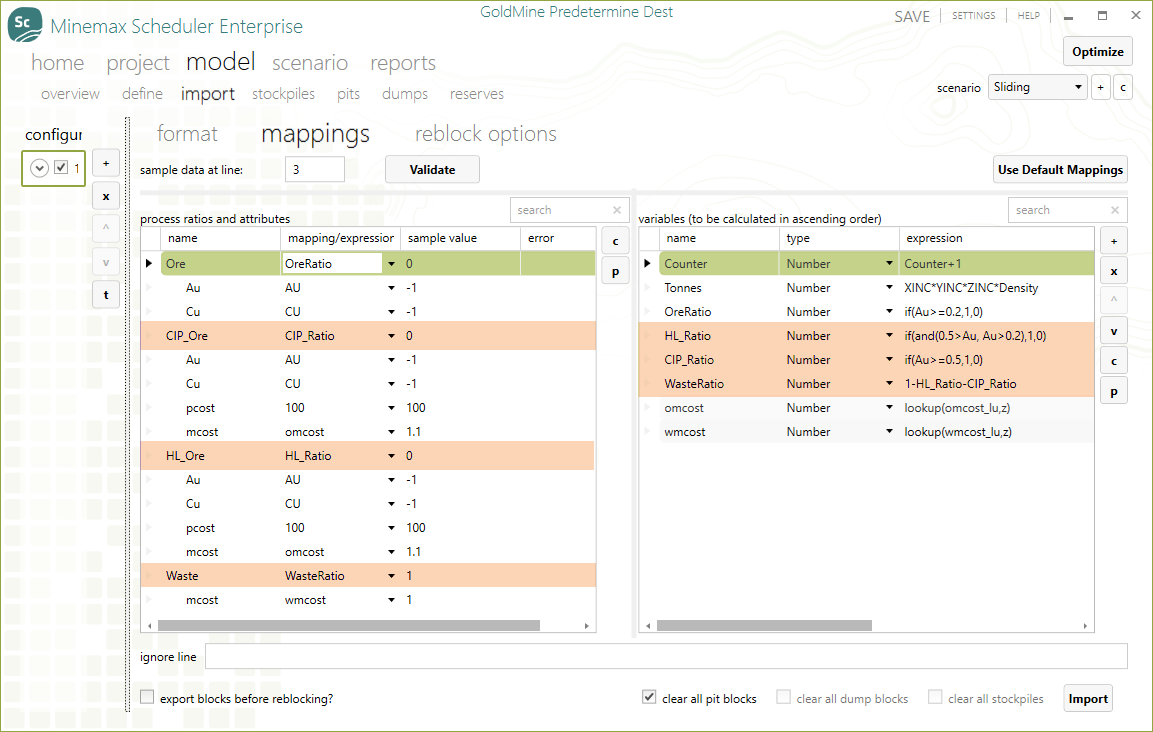

Let’s start with a model of a traditional gold mine that includes CIP, HL and a waste dump destinations. The destinations are pre-determined by defining them as mining processes on the Define screen and then mapping them to defined values on the Mappings screen.

On the Mappings screen, the CIP, HL and waste destinations (CIP_Ore, HL_Ore, Waste) are mapped to process ratios with values ranging between 0 and 1 depending on the material grade. Process ratios are then multiplied by the mass of each block to give the total quantity of material from the block that is sent to the destination. Let’s look at process ratio values for a sample block with 10,000 tonnes:

| Au ≥ 0.5 | CIP_Ratio = 1 , HL_Ratio = 0 , WasteRatio = 0 | CIP Ore Block Mass = 10,000 tonnes |

| 0.2 < Au < 0.5 | CIP_Ratio = 0, HL_Ratio =1, WasteRatio = 0 | HL Ore Block Mass = 10,000 tonnes |

| Au ≤ 0.2 | CIP_Ratio = 0, HL_Ratio =0, WasteRatio = 1 | Waste Block Mass = 10,000 tonnes |

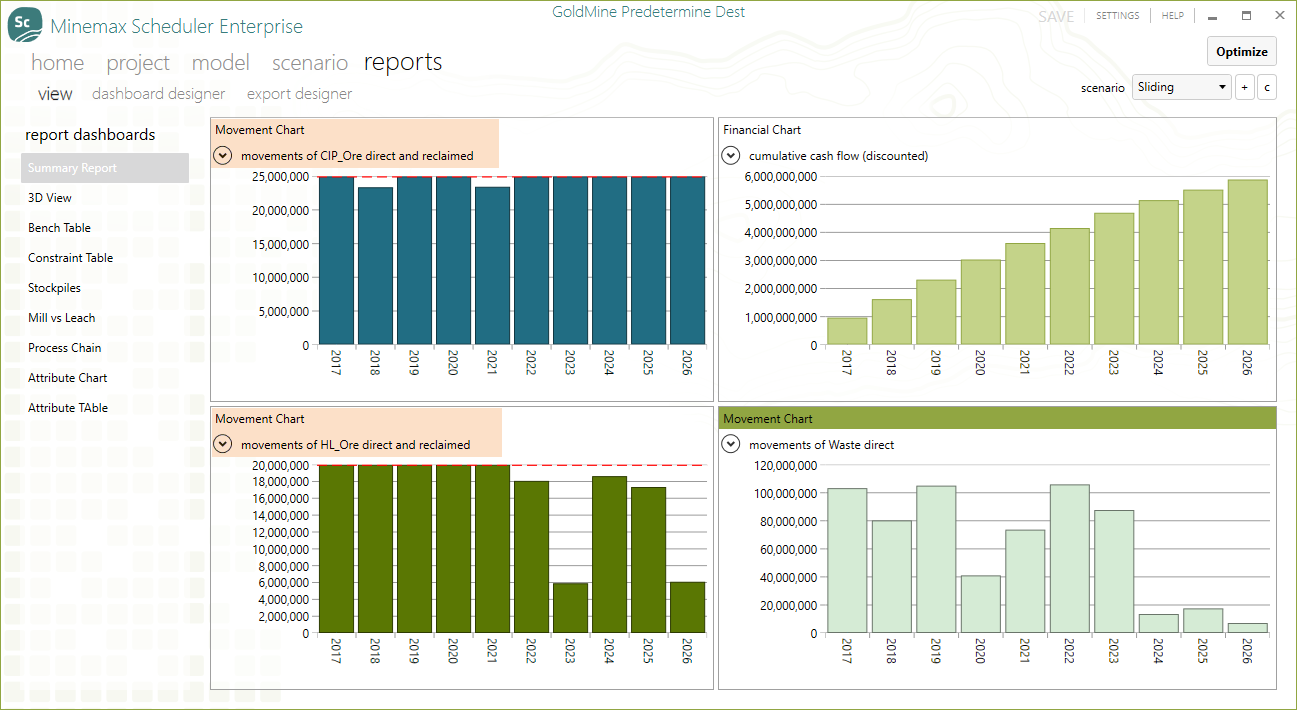

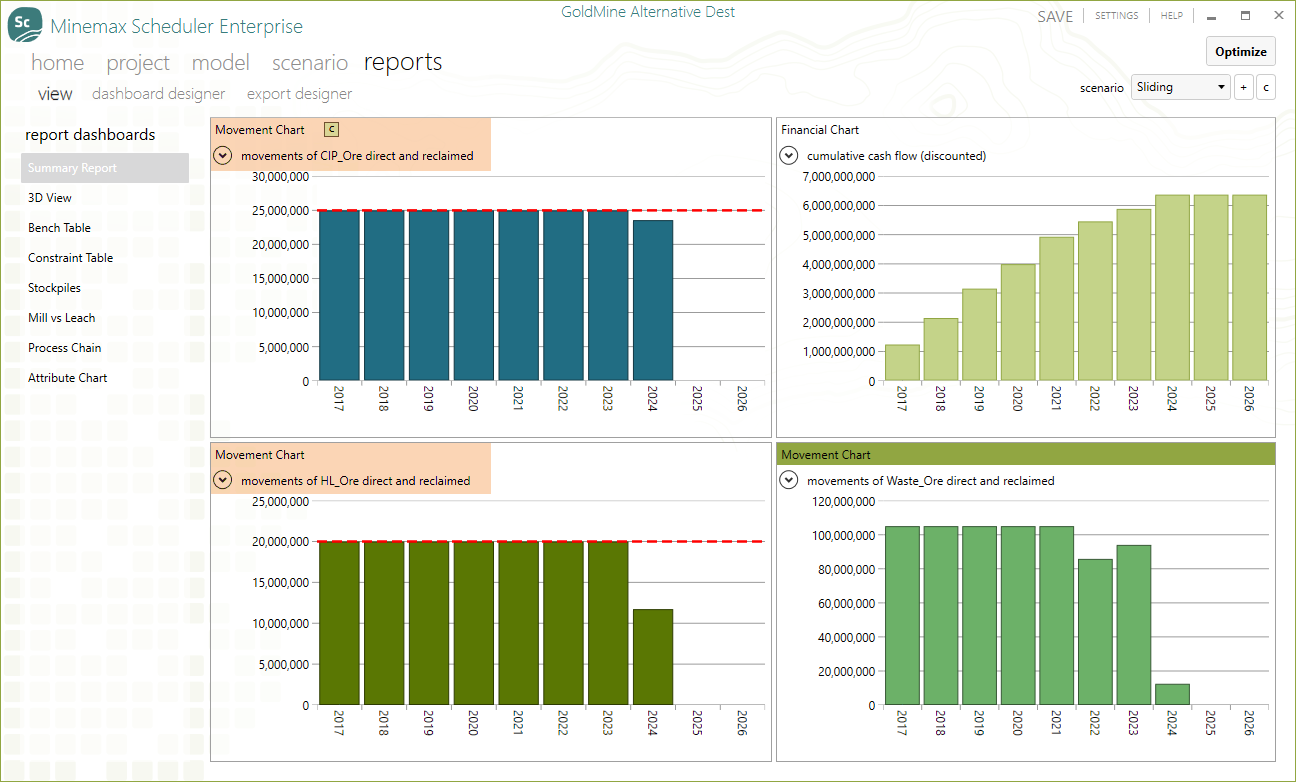

When we optimize the model in Minemax Scheduler considering financials, precedences and constraints, we get a schedule with the total NPV of $5,886,137,454 satisfying processing constraints for the CIP and HP plants as shown below.

Modeling Alternative Destinations

Now we’ll clone the project and go back to the model definition to set up alternative decisions to determine material destinations as an output of the optimization process.

In Minemax Scheduler, we can do this by following these easy steps:

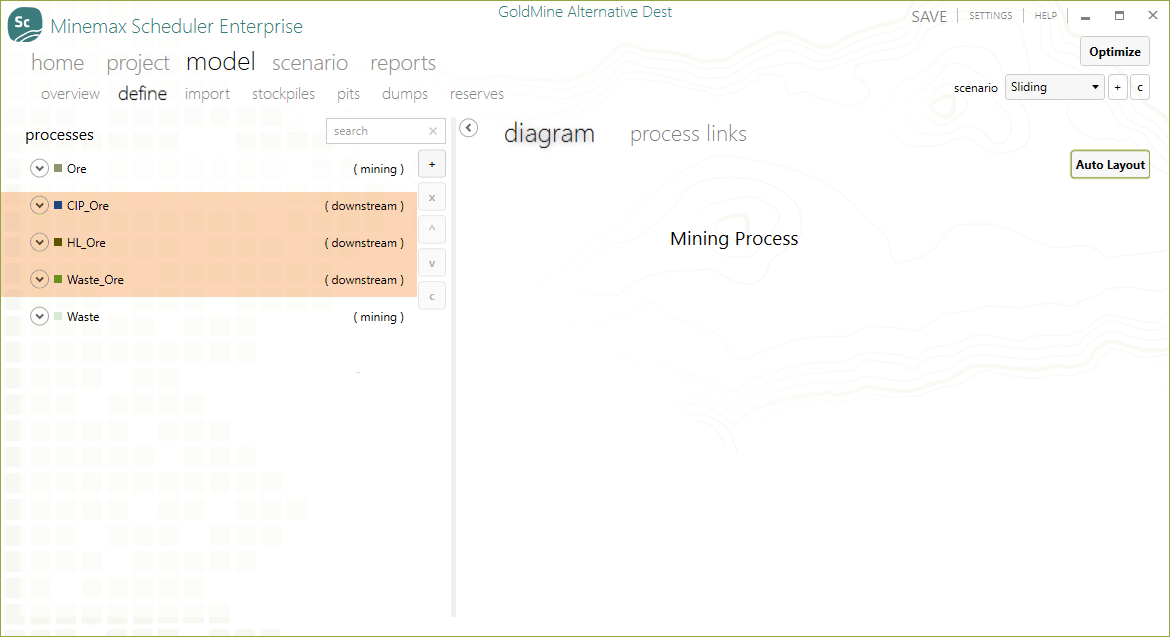

- On the Define screen in the Processes section, change the process type from ‘mining’ to ‘downstream’ for the processing destinations CIP_Ore and HL_Ore .

- On the same screen, create a new ‘downstream’ waste destination Waste_Ore. The last default Waste process in the list is only used for pre-determined waste which we don’t have in this example.

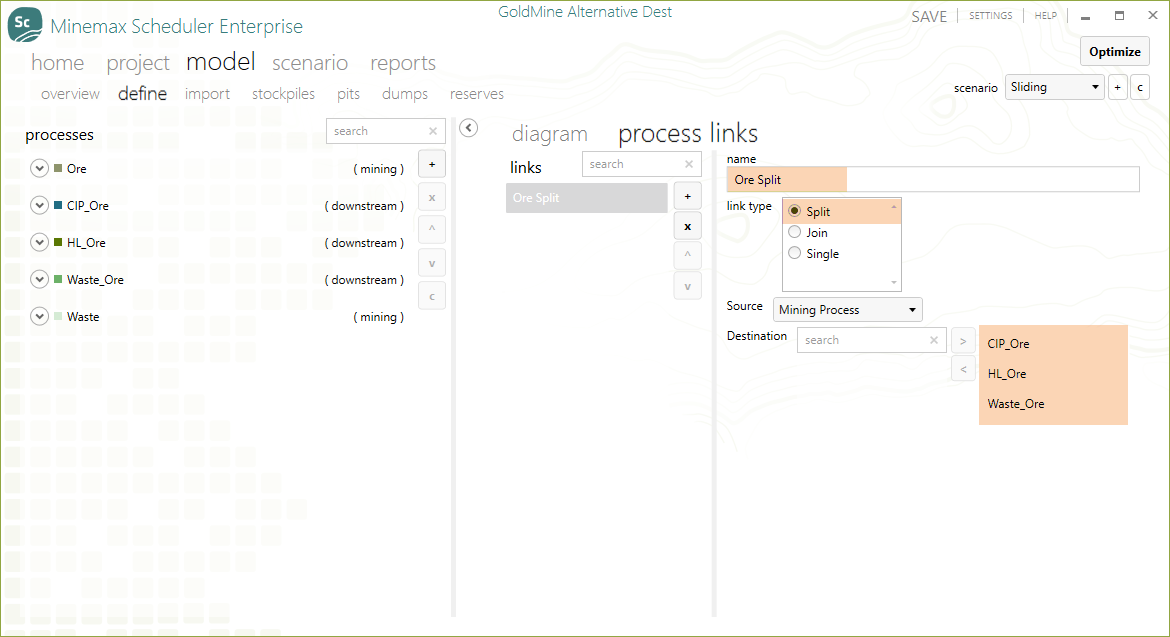

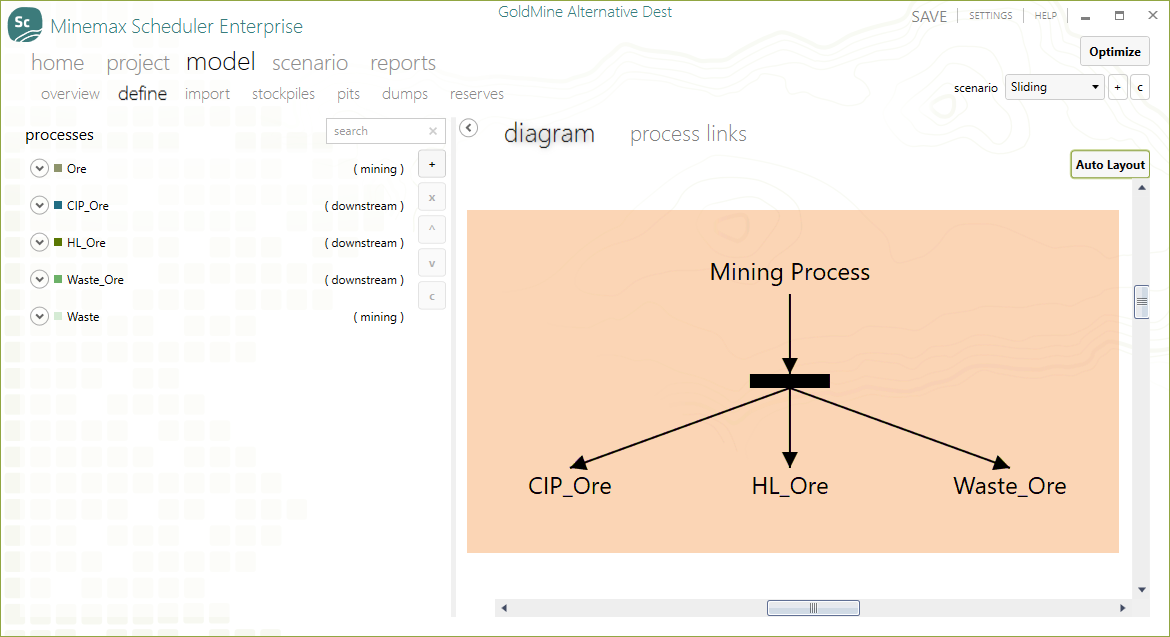

3. In the Process Links section, create process links to define the logical relationships between destinations using a decision tree diagram.

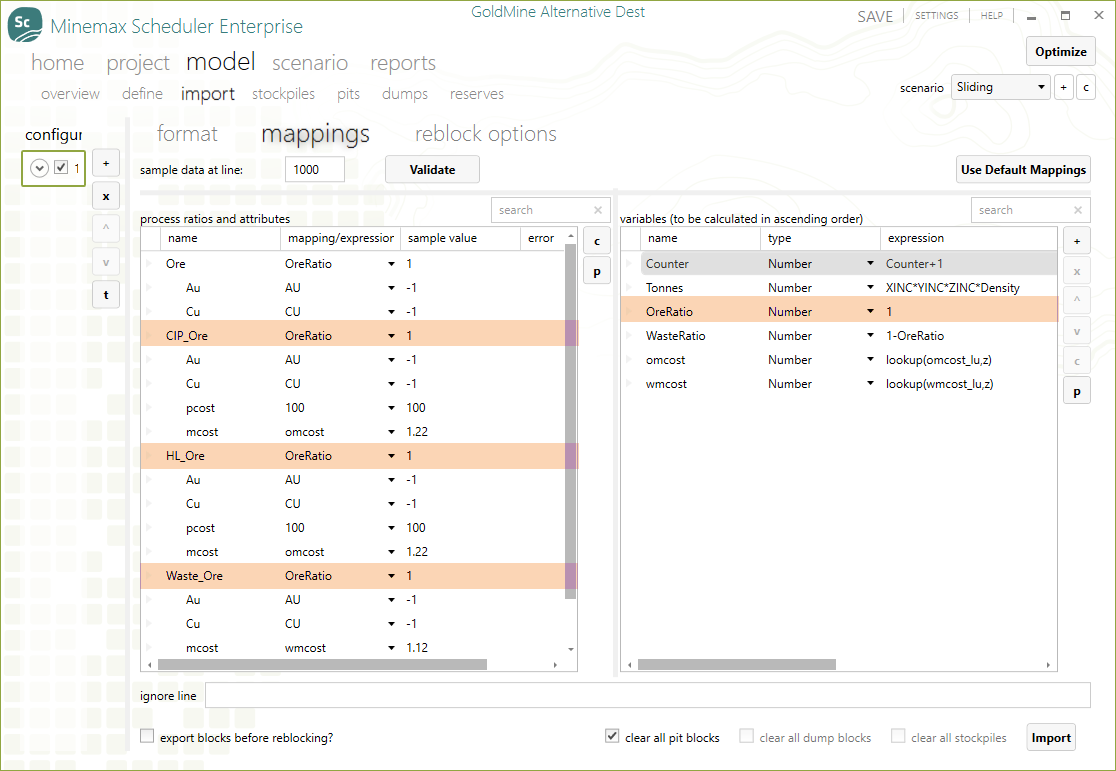

4. On the Mappings screen, map all three destinations CIP_Ore, Leach_Ore and Waste_Ore to the ‘OreRatio’ process ratio which is set to 1. This means that it is possible for each block to go

to any of these three destinations.

5. Click the Import button to import the new model definition so we can move on to the schedule optimization.

Scheduling with Alternative Decisions

During the optimization, Minemax Scheduler decides when each block is mined based on financials, precedences and constraints. When alternative decisions are used in the project, decisions as to when each block is mined and where it is going are considered within the same optimization run.

For our example, the resulting schedule with alternative decisions gives the total NPV of

$6,372,484,922 which is an improvement of more than $486m over the previous schedule.

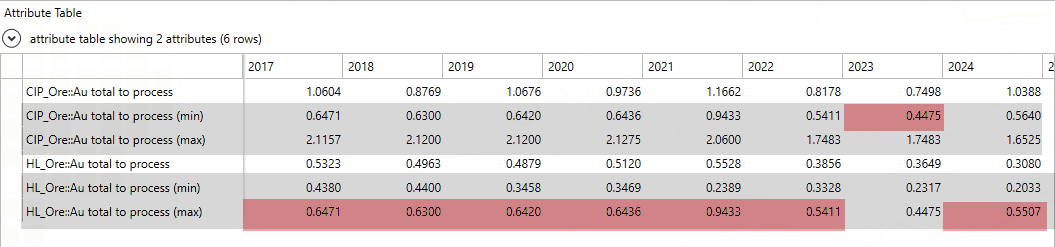

The Attribute Table report below shows that the optimal cut-off grades for CIP, HL, and Waste destinations are not fixed, but they change over time to produce the best high-value schedule possible. To achieve this, the CIP and HL plants also process various grades (highlighted in red) with values above or below the pre-determined cut-off grade of 0.5 g/t set up in the first scenario.

Summary

In this short article you have seen an easy, yet valuable way of modelling alternative destinations in your strategic mine plan. By integrating the decisions about material destinations into your schedule optimization, and by treating them as an output rather than an input, you are able to produce a practical schedule with a significantly greater value for your project or operation.

Alternative decisions in Minemax Scheduler have many different applications, from the simple example shown today to far more complex models including decisions for trucking routes, alternative products, and processing methods.

If you’d like to know more about Minemax Scheduler, you can download Minemax Scheduler Viewer and explore some more examples.

If you’d like to discuss how to use alternative decisions in your specific situation, contact one of our mining engineers who are always ready to help.