Any coal mine planning engineer would agree that mine planning in coal presents unique challenges that aren’t issues in metals mining. In particular, shallow dipping deposits just aren’t mined the way deep metals mines with multiple stages are mined – and the mine plan needs to reflect how the deposit can actually be mined.

So how do you quickly go from a resource model to a life-of-mine plan that’s operationally “doable”? The tools you use need to address economics while at the same time giving a plan that makes sense.

Enter the Minemax Planner and Tempo Dynamic Duo. Minemax Planner for pit optimization has been used to generate optimal pit shells since 2001. Recent developments in its optimization engine enable it to run extremely quickly on very large block models. This is important for coal models where your bench height can be 1m or less, giving 10’s of millions of blocks.

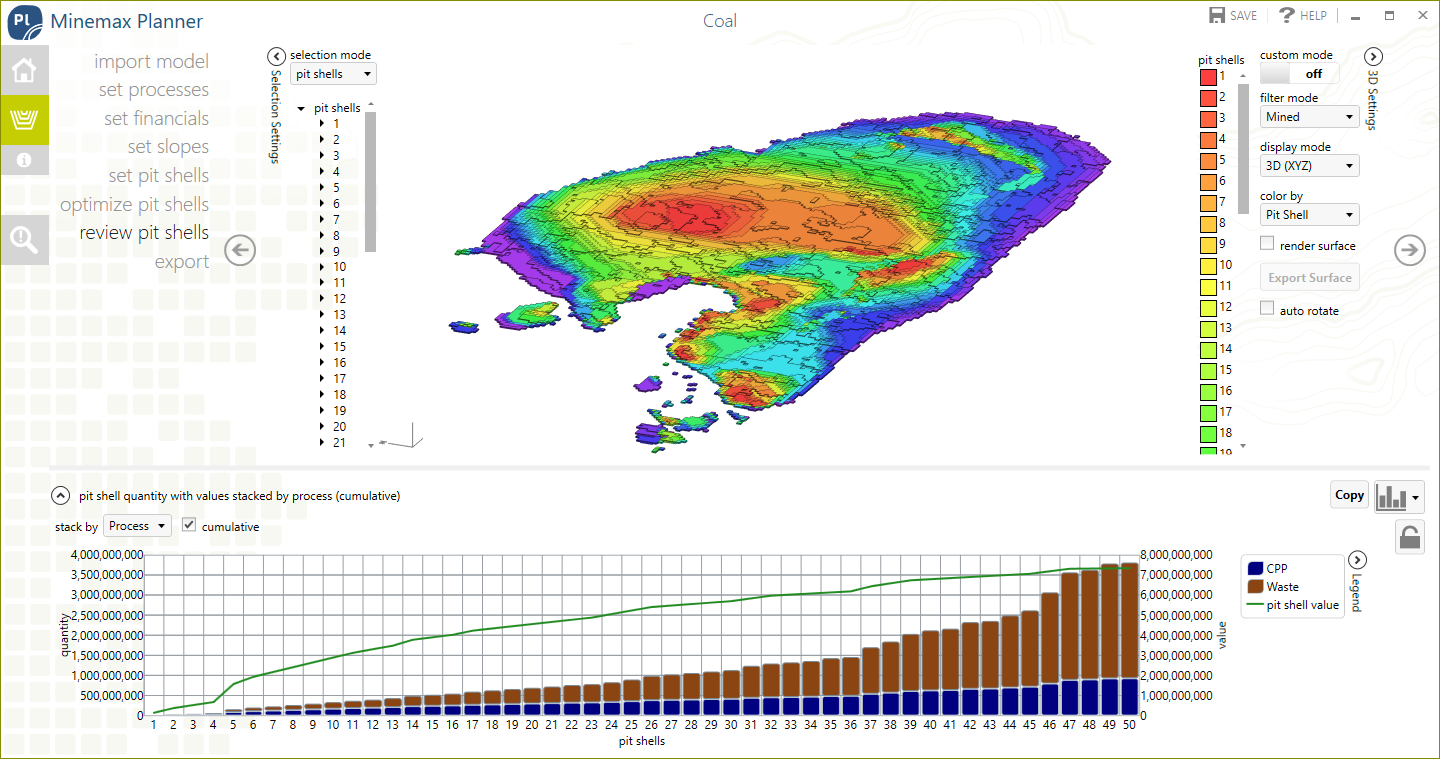

In the example below, you can see a series of 50 pit shells in Minemax Planner showing the sensitivity to varying coal prices. This model has a little more than 1.3 million blocks and with no reblocking, the 50 shells were generated in less than a minute on an average laptop. That’s about a second per shell for a 1.3 million block model. Clearly, long pit optimization run times are a thing of the past.

Once a pit shell is chosen, we want to quickly get a feel for both the physicals and the economics of a life-of-mine plan. Now it’s time for Tempo to take over. Tempo is an easy-to-use tool for detailed mine planning. It works with regularized block models or polygons with associated reserves. In this case, we’ll go with the block model option. The pit shell we select from Minemax Planner is exported into a csv file that Tempo can directly import.

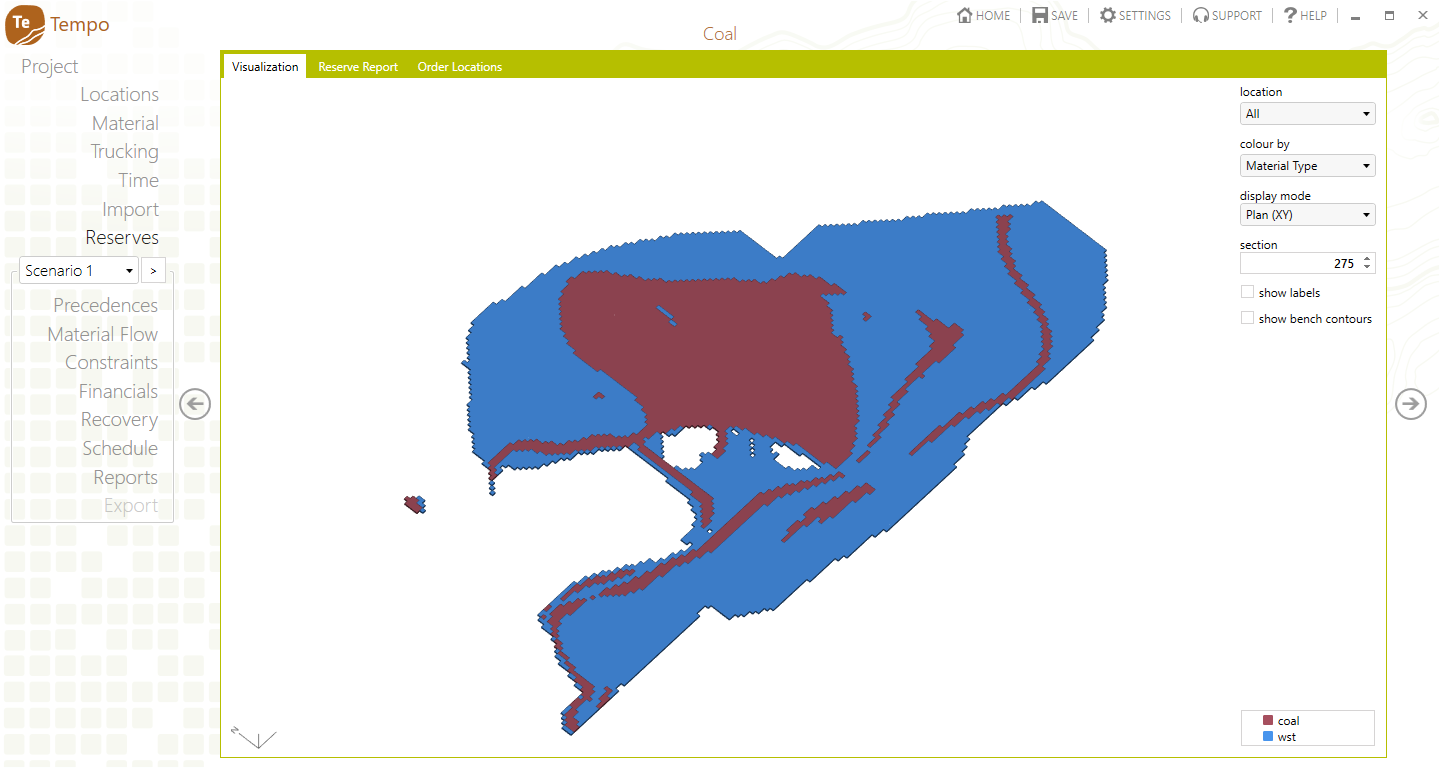

The screen grab below shows a plan slice of the model in Tempo where a number of seams are visible.

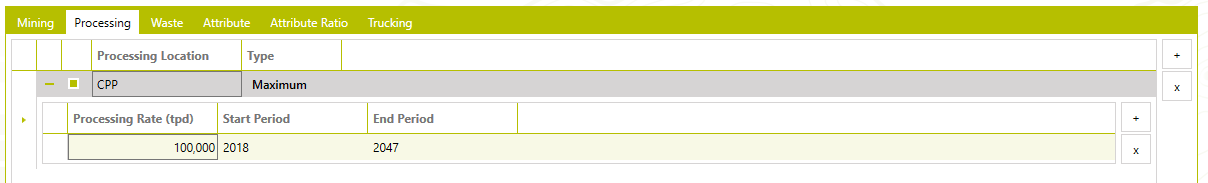

To go from here to a life-of-mine plan just means setting a few constraints and letting Tempo do the rest. We set a mining constraint, a processing constraint for the CPP, and precedence constraints associated with mining logic.

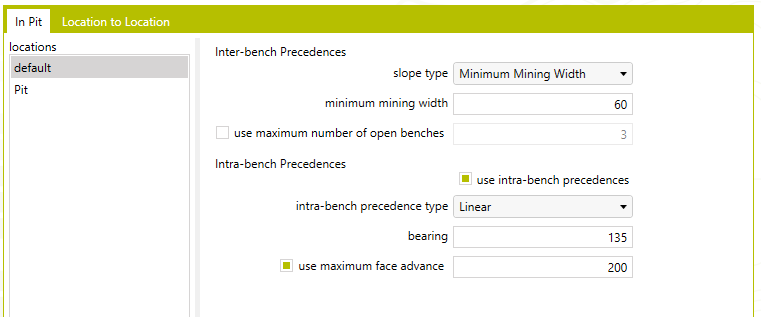

The maximum face advance constraint in Tempo has been designed to give practical schedules when mining in long shallow tabular deposits, so we use that and set the maximum advance to 200. In this example the model units are metres, so it is 200 metres. If the model units were feet, the maximum advance would be in feet.

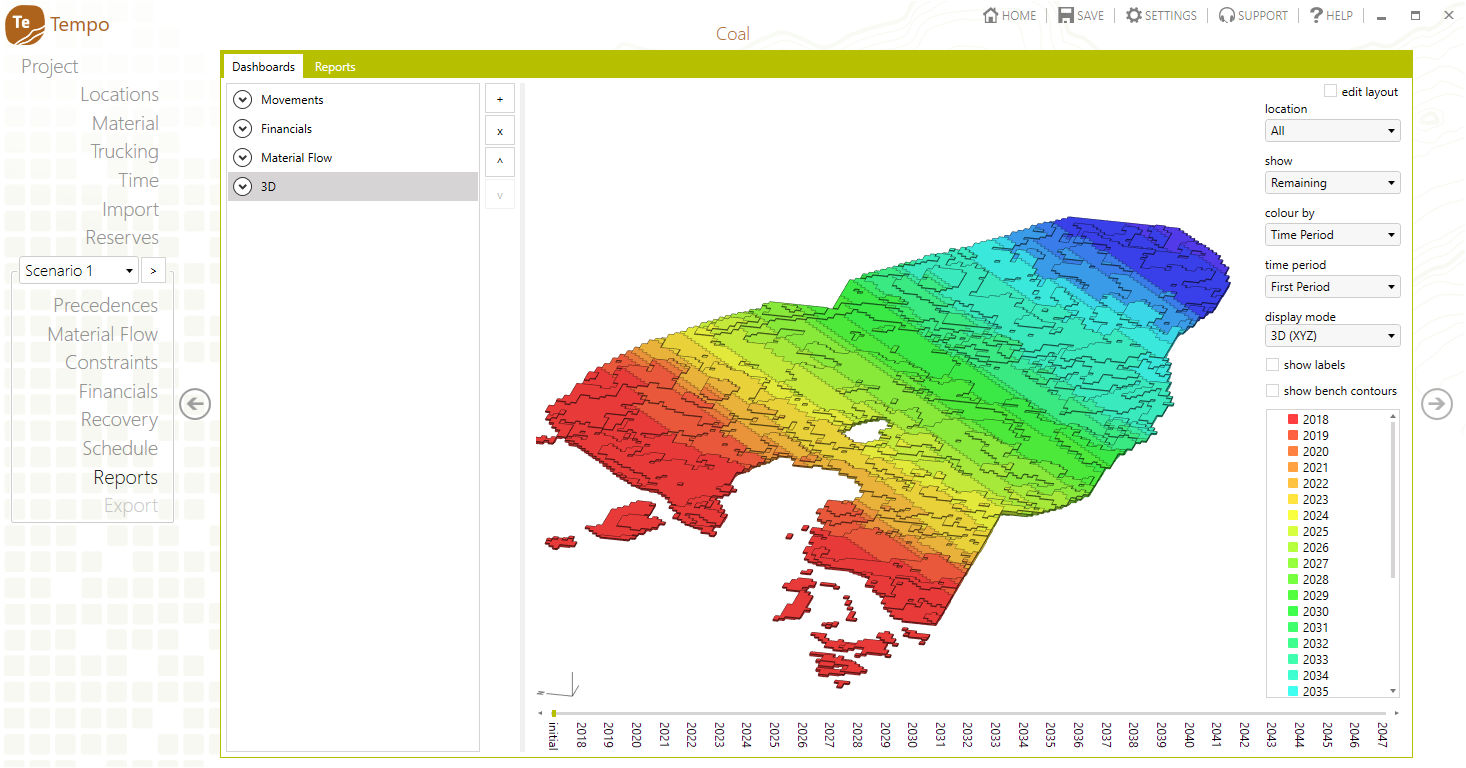

Generating a 30 year schedule in Tempo takes just a few minutes using its fast scheduling engine. The schedule is value driven and respects mining and processing constraints. This project is for thermal coal. If we had coking coal with blending constraints on ash, we could put limits on ash as well. The image below shows the model with blocks colour-coded by time period. The direction of mining from red to blue should be clear as should the maximum face advance constraint. If we wanted to spend a little more time, we could have divided up the deposit into two or three strips that could progress independently.

This was just a quick snapshot into how you can use Minemax Planner and Tempo together for easy and effective mine planning in coal.

Learn more, find out about pricing, or try a demo of Minemax Planner or Tempo.

Or if you want to ask a quick question, reach out to us on this link.