We all know silo organizational structures and processes drain time and value from companies. Mine planning is no exception. There are different time horizons of planning: strategic, long-term, medium-term, short-term and short interval control. Each horizon is typically run by a different person. Without a means of integrating the different time horizons, silo planning can result in inefficiencies and lost business value.

The same can be true of a single planning horizon. For example, let’s look at strategic planning. Even though strategic planning may be a silo in the overall mine planning process, it can also have its own silos. To identify these silos, let’s think about the many value levers in a strategic plan.

- Mine schedule: when a block is mined.

- Destination schedule: where a block goes and how it is processed, if ore.

- Haulage plan: how trucks are used to achieve the mine plan.

- Waste management plan: where specifically to dump waste material given options of multiple ex-pit and in-pit dumps.

- Capital expenditure plan: how to most effectively invest capital in equipment and infrastructure.

Many mining companies treat some of these value levers as silos from a mine planning point of view. When one silo’s planning is complete, that part of the plan is used as content for the next silo. This approach is time-consuming, inefficient, and can lose a tonne of business value. It doesn’t have to be that way!

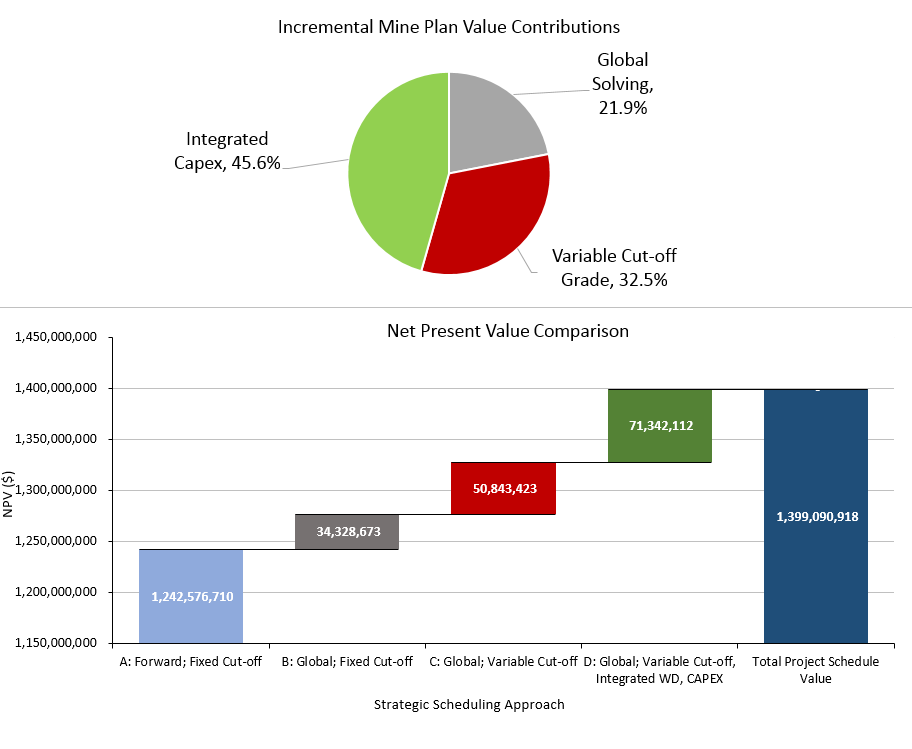

In an earlier article, we showed how you can use all strategic planning value levers simultaneously instead of sequentially across silos. We used Minemax Scheduler for that exercise.

How does your company consider strategic mine planning value levers? Are there still silos or are you on the journey to an integrated approach to strategic mine planning? If you’d like find out how to start that journey, reach out to us.